About safety helmets (I)

When we talk about personal protective equipment in the workplace, possibly the first PPE we think of is the helmet. And it’s logical since the head is the most important organ in our body: the brain.

In this series of articles we aim to briefly and simply explain the different types of protective helmets that exist in the workplace, the regulations they comply with and, most importantly, what is behind those numbers that we often overlook. At the end of the day, the choice of a PPE should never be conditioned by a price issue, but by the results of the previous risk assessment study carried out by the company’s manager or prevention team. By strictly applying this criterion, we will undoubtedly avoid accidents, and, most importantly, we will be more protected against any eventual fatality that may occur.

What type and model of helmet to choose?

In the workplace, the worker’s head can be exposed to risks of different nature, being the most common ones:

- Impacts from falling objects

- Crashes

- Lateral trapping

- Electrical risks

- Chemical risks

In view of this, protective helmets must comply with the requirements and regulations in force in the country or countries where they will be used. In the case of the European Community, Directive 89/656/EEC establishes the minimum health and safety requirements for the use of personal protective equipment by workers. And Decree 773/1997 is the text that transposes it into Spanish law. The main European regulations governing protective helmets can be divided into two main groups:

Group 1: Helmets for Industry

EN 812:2012 Industrial Impact Helmets

EN 397:2012+A1:2012 Industrial safety helmets.

EN 14052:2012+A1:2012 High Performance Helmets for Industry.

Group 2: Helmets for Specific Applications

EN 50365:2002 Electrically insulated helmets for low voltage use

EN 12492:2012 Helmets for mountaineers.

EN 443:2008 Helmets for fire fighting in buildings and other structures.

EN 16471:2014 Protective helmets for forest firefighters.

EN 16473:2014 Protective helmets for technical rescue.

In this first article, in order not to make it too long, we will focus exclusively on the first group: Helmets for Industry. We will soon publish a second article on the Helmets for Specific Applications (second group).

EN 812:2012 Standard: Industrial Impact Helmets

Commonly referred to as “Impact Protection Caps” because of their design, they offer protection against impacts from stationary objects that may cause superficial injuries or lacerations.

Different cap options.

They are not certified for protection against falling or projected objects or suspended or moving loads. They only protect against impacts from fixed objects.

The protection caps are suitable for maintenance work where the use of the industrial safety helmet according to EN397 is not mandatory, such as in the food industry, automotive industry, assembly lines, etc.

Standard EN 397:2012+A1:2012. Industrial Safety Helmets

It is the main European standard regulating head protection equipment. All helmets approved according to EN397 must pass the following mandatory tests for impact resistance and puncture resistance (although only on the top part of the helmet (peak) and for resistance to flame contact:

Industrial safety helmets.

- Impact cushioning test: A 5 kg hemispherical firing pin is dropped on the crest of the helmet from a height of 1 m. The force transmitted to the test head must not exceed 5000 N (5 kN).

- Penetration resistance test: A 3 kg conical firing pin is dropped onto the crest area. The firing pin must not come into contact with the test head.

- Flame resistance test: The helmet is exposed to a flame for 10 seconds and when removed, the shell must not burn or the flame must extinguish itself within a maximum of 5 seconds.

Additionally, EN 397 contemplates other optional tests: resistance to impacts at very low and very high temperatures, electrical insulation (440V in AC), lateral deformation and resistance to molten metal splashes.

EN 14052:2012+A1:2012 High performance helmets for industry

Compared to EN397, EN14052-certified high-performance industrial helmets offer increased protection against impacts from falling objects, even outside the summit area (15° to 60° from the vertical axis), as well as against drilling on and off the summit.

They must also include a retention system (chin strap) with an opening resistance of between 15kN and 25kN to avoid strangulation of the worker in the event of the helmet being caught and that it does not come off the head.

High performance helmets.

Helmets certified according to EN14052 have the same flame resistance properties as EN397 industrial protection helmets, and offer the same optional protection against other hazards, except for requirements against side deformation, where EN14052 is much higher.

As is to be expected, in order to achieve these higher protection levels, high-performance industrial helmets are manufactured using innovative design methods and materials of higher resistance than those used in “basic” protection helmets: outer shells made of ABS or glass-fibre reinforced polypropylene, inner shells made of high-density polystyrene, etc…

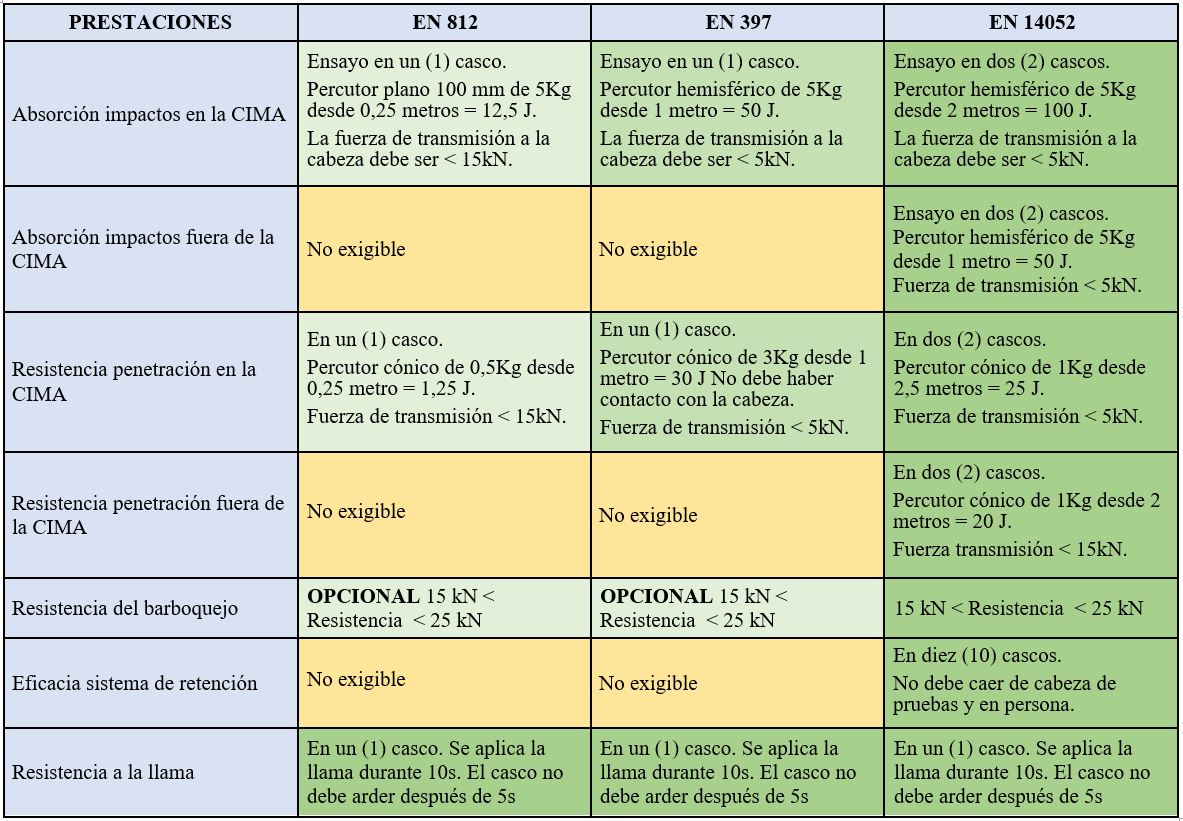

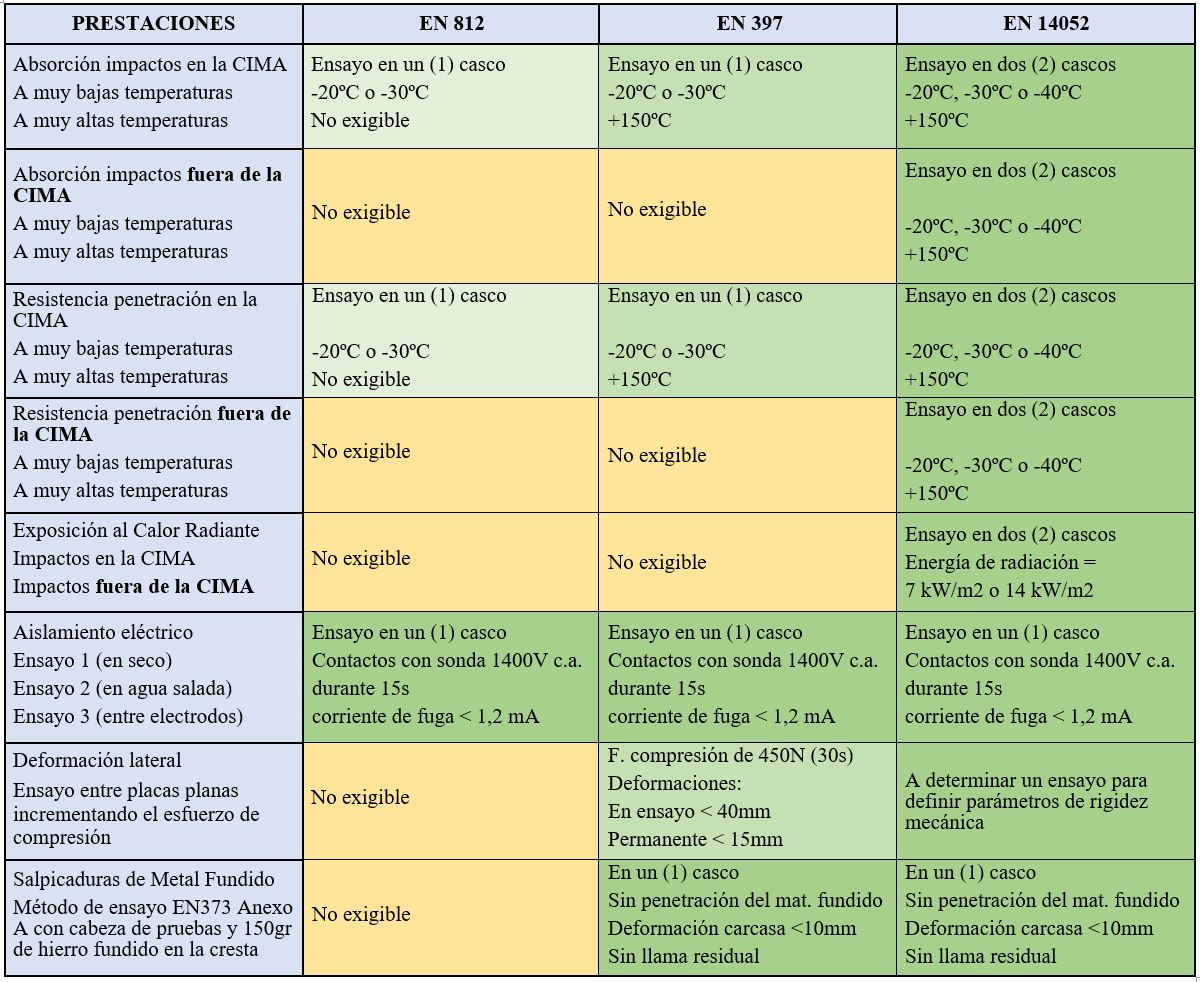

COMPARATIVE HULL TESTING FOR INDUSTRY

In the following two tables we can see a quick summary of the mandatory and optional requirements for industrial safety helmets:

In view of this comparison of requirements and demands between the different standards, we can provide the following conclusions:

EN397 was written in 1995 and since then there have been few changes in the requirements of this standard. Therefore, as with all other protective equipment standards, EN 397 is not the highest applicable safety level, but on the contrary, the lowest level required.

It is essential to carry out a correct risk assessment by the company’s prevention manager, determining all the dangers to which the worker may be exposed and in this sense prescribing the appropriate PPE.

At PERTESA we believe that some of the optional requirements for industrial helmets should be made obligatory, as is the case with the use of chin protector, as we understand that its use considerably improves the safety of the worker, guaranteeing the correct position of the helmet on the head and avoiding its loss in the event of a blow, which would expose the worker to possible subsequent impacts.

In the second part of this article we will talk about the second group, the one corresponding to the Helmets for Specific Applications.